Industrial filtration applications of PORAL sintered components

Poral components are high-performance porous sintered components designed for a wide range of industrial filtration applications. They are used across numerous sectors, including aeronautics, pharmaceuticals, food processing, water treatment, and more.

All our filtration

applications.

Thanks to their unique porous structure, PORAL’s sintered filters are suited to a variety of functions such as filtration, fluidization, aeration and more. This versatility explains their widespread adoption in so many industries.

Filtration and

Separation.

Porosity is capable of retaining solid particles contained in a liquid or gaseous fluid and partially separating gaseous phases of different molecular weights. This property is used to filter fluids with very diverse characteristics.

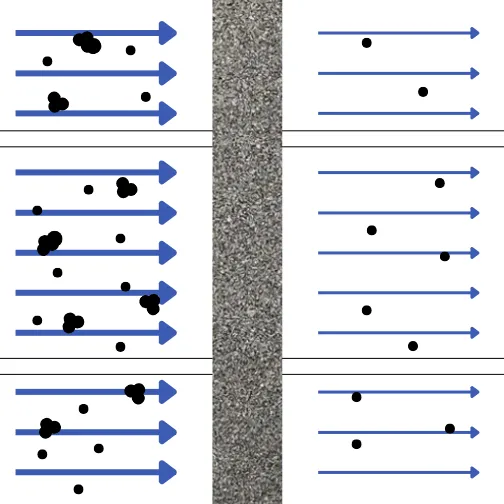

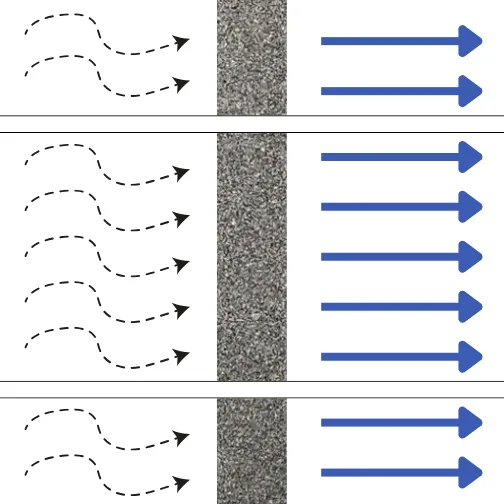

Filtration

When the particle size is smaller than the pore size, the particles penetrate through the porosity of the filter media. Particles encounter many obstacles, and are retained in the thickness of the filter.

Seperation

When pore size is smaller than particles to be filtered, they are retained on the surface of the filter. Back flush cleaning is readily performed.

Gas

Bubbling.

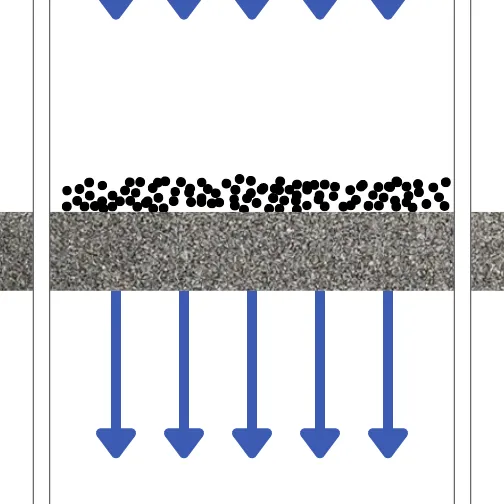

Bubbling with porous sintered materials involves dispersing a gas into a liquid through a fine porous structure. The gas is forced through the tiny, interconnected pores of the sintered element, creating numerous small and uniform bubbles.

This process increases the gas-liquid contact surface area, which enhances mass transfer efficiency. It is commonly used for aerating liquids, promoting chemical reactions, or maintaining dissolved gas levels in applications such as water treatment.

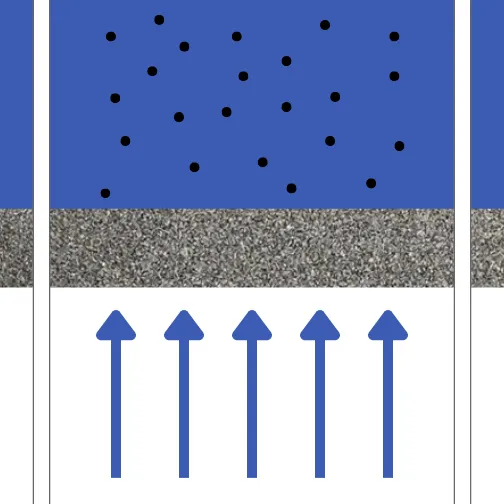

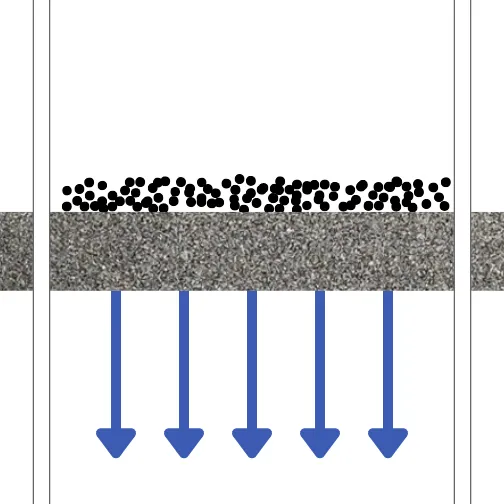

Fluidization.

Solids particles are converted from a static state to a dynamic state.

The advantage of the fluidized state is that the solids particles have similar flow properties to those of a liqui phase. The fluidized state begins when the gas velocity is sufficient to be able to carry solid particles.

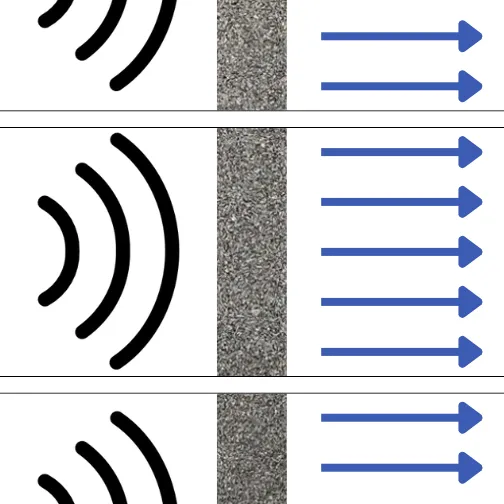

Noise

Reduction.

PORAL porous sintered filter allow noise reduction by reducing the pressure. The efficiency will depend on filter features.

Aspiration.

PORAL sintered porous components can be used in aspiration processes to selectively capture and retain moisture or liquid particles suspended in a gas stream. Thanks to their controlled pore size and high surface area, these porous elements act as efficient barriers, allowing gas to pass through while trapping fine droplets or vapors.

This moisture retention capability helps protect sensitive downstream equipment, prevent contamination, and improve the performance of pneumatic or vacuum systems.

Such applications are commonly found in air drying, gas purification and analytical instrumentation.

Flow

control.

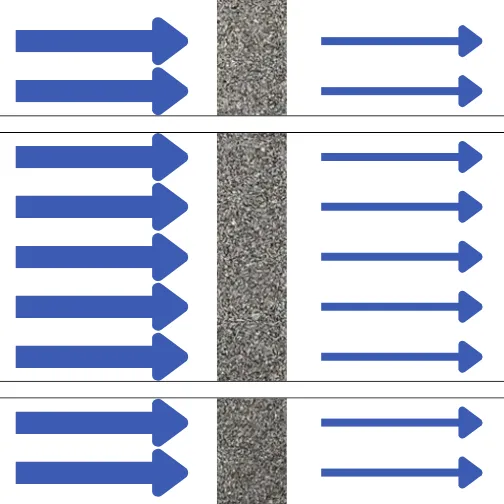

PORAL sintered components can be used to achieve precise and consistent flow control in industrial applications. Thanks to their highly uniform and interconnected pore structure, these porous materials regulate the passage of gases or liquids, ensuring a stable and controlled outflow over time.

Unlike conventional flow restrictors, sintered porous elements provide improved reliability by minimizing pressure fluctuations and reducing the risk of clogging.

This makes them ideal for applications such as gas dosing, pressure equalization, and fluid metering in sectors like chemical processing, automotive, and medical devices.

Flow

Restriction.

Our components are ideal for flow restriction through controlled pressure drop. Their calibrated and tortuous pore structure creates a natural resistance to fluid flow, allowing for precise regulation of flow rates without moving parts.

This passive flow control is particularly beneficial in systems velocity, or balance flow distribution across multiple channels.

Discover our products

and materials.

Our sintered porous components come in a variety of forms and are manufactured from bronze, stainless steel or alloy.

Materials

Components

materials.

Different types of material can be used for our porous sintered components, depending on the type of application and the desired technical characteristics.

Bronze, stainless steel, alloy… Find out more about the advantages and characteristics of each material.

Products

Our components

ranges.

PORAL offers a full range of porous sintered components available in various shapes and materials. Designed to meet the demands of diverse industrial applications, our complete product offering is detailed on this dedicated page.

Do you have a question or a project?

Access our contact form and our teams will get back to you as soon as possible.