Sintered filters for industrial filtration

PORAL® designs and manufactures high-performance porous sintered filters for industrial filtration and a wide range of related applications. Available in stainless steel, bronze, and other alloys, and in various shapes such as tubes, discs, cartridges, and custom parts, PORAL solutions deliver reliability and versatility across demanding industrial environments.

Our range of porous

sintered filters.

PORAL offers a wide range of porous sintered filters manufactured from stainless steel and bronze. Available in various shapes both standard and custom parts, our components are designed to meet the needs of multiple industrial filtration applications. Whether for filtration, flow control, gas diffusion, or noise reduction, PORAL products deliver consistent performance and long-term durability across demanding environments.

Products

Stainless Steel &

nickel-based alloys filters.

PORAL® stainless steel sintered filters are engineered for high-performance filtration in demanding industrial environments. Thanks to their controlled porosity and robust construction, they provide consistent flow rates and excellent filtration efficiency. These filters are ideal for applications in fluid processing, gas filtration, and protective component systems.

Available in a wide range of dimensions and shapes, they can be customized to meet specific mechanical and functional requirements.

Our manufacturing expertise ensures precise, repeatable quality, making stainless steel sintered filters a reliable choice for both standard and complex filtration needs.

Products

Bronze

Filters.

PORAL® bronze sintered filters combine mechanical strength and controlled porosity to deliver dependable performance in air, fluid, and gas filtration. They are well-suited for applications such as noise reduction, flow regulation, providing consistent results even in demanding operating conditions.

Available in both standard designs and fully custom-made solutions, bronze filters can be produced in a variety of shapes and sizes to integrate seamlessly into your system.

With our expertise in manufacturing and customization, PORAL® bronze filters can be tailored to meet the unique requirements of your process or application.

Process of Sintering

Typical microstructure of

sintered metal filters.

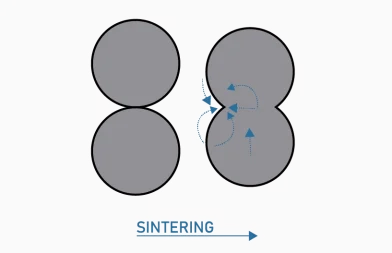

PORAL metal filters are produced using powder metallurgy. This process consists of two main steps: shaping powdered materials and sintering. Shaping can be carried out in different ways depending on the alloy in question: cold isostatic or uniaxial pressing, gravity filling. Sintering is a heat treatment consisting of heating the part to a temperature below the melting point of the base metal in a controlled atmosphere. The heat treatment allows the atoms to diffuse in the solid state, creating sintering bridges between the powder particles, thus ensuring the cohesion of the part.

Schematic representation of sintering mechanisms

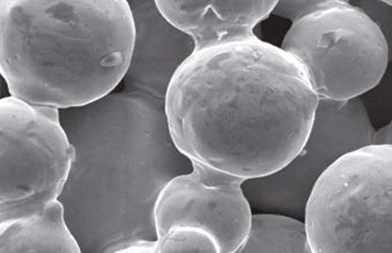

Microstructure of Bronze PORAL® filters after sintering.

Gr. 15- x 250

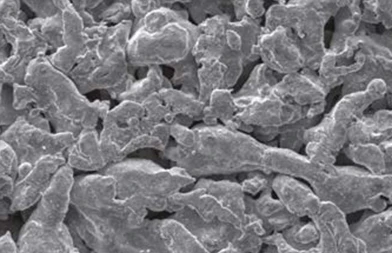

Microstructure of Stainless steel & Ni alloys PORAL® filters after sintering.

Gr. 15- x 100

PORAL sintered Filters

Advantages.

High temperature resistance

High temperature resistance, stability over a wide temperature range from cryogenic to high temperature (from 150°C to 900°C).

Filtration efficiency

High filtration efficiency, from 0.2 to 270 µm depending on material and grade.

Corrosion resistance

High corrosion resistance, chemical stability.

Mechanical resistance

High mechanical strength, high differential pressure capacity, vibration and abrasion resistance.

Easy to clean

Easy cleaning for significant operating cost savings by reverse flushing with clean fluid, suitable solvents, chemical reagents, ultrasonic washing or calcination (long service life).

Easy to implement

Easy to implement in any installation design (machinable and weldable, complex shapes).

Homogeneity

Regular behavior, homogeneous distribution of porosity.

Do you have a question or a project?

Access our contact form and our teams will get back to you as soon as possible.