Materials for porous sintered components

The choice of material is a key factor in the performance, durability, and compatibility of porous sintered components. At PORAL, we manufacture our products using high-quality stainless steel, bronze, and selected alloys.

Porous sintered

component materials.

Each material offers specific advantages to meet the technical and environmental requirements of various industrial applications. Explore our materials to find the best fit for your needs.

Stainless steel components

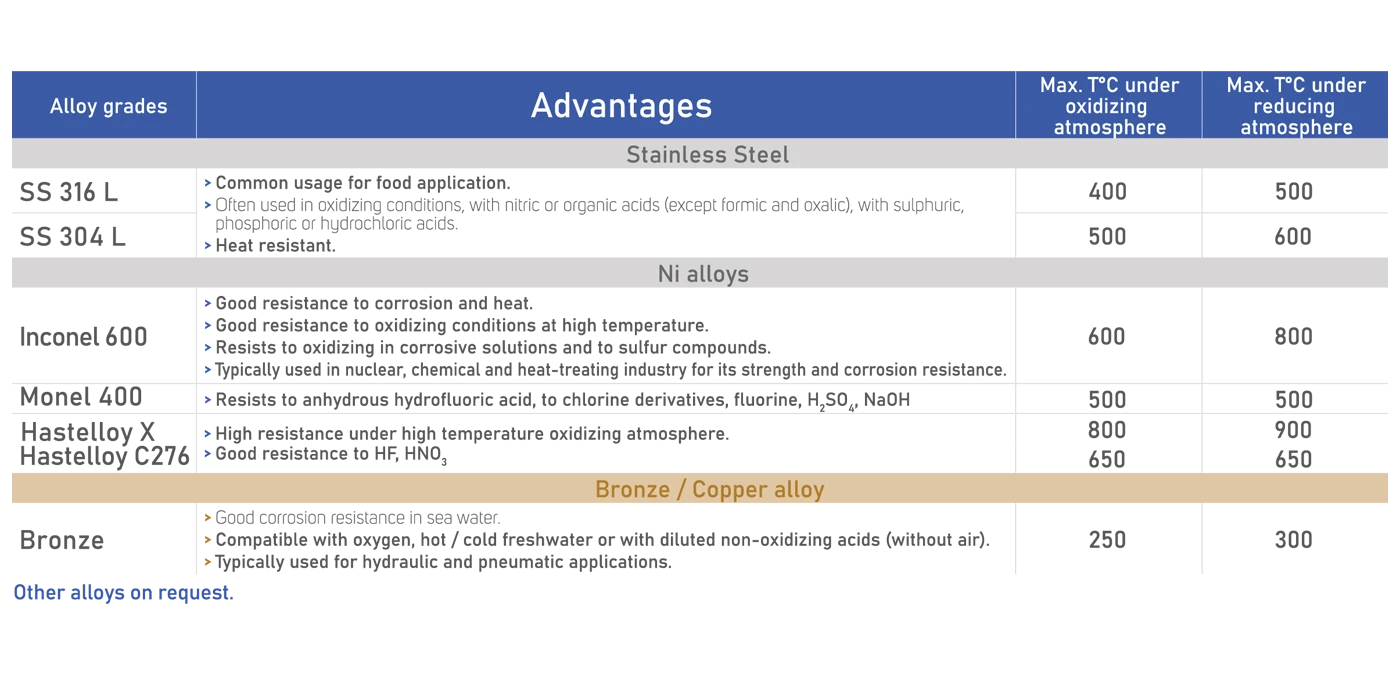

Common usage for food application. Often used in oxidizing conditions with nitric or organic acids (except formic and oxalic) with sulphuric phosphoric of hydrochloric acids, heat resistants.

Bronze components

Good corrosion resistance in sea water. Compatible with oxygen, hot/cold frashwater or with diluted non-oxidizing acids (without air). Typically used for hydraulic and pneumatic applications.

Inconel components

Good resistance to corrosion and heat. Good resistance to oxidizing conditions at high temperature. Resists to oxidizing in corrosive solutions and to sulfur compounds.

Typically used in nuclear, chemical and heat treating industry for its strenght and corrosion resistance.

Monel 400 components

Resist to anhydrous hydrofluoric acid to chlorine derivatives, fluorine, HeS04; NaOH

Hastelloy X components

High resistance under high temperatures oxidizing atmosphere.

Hastelloy c276 components

Good resistance to HF, HN03.

PORAL GRADES

Material selection &

filtration efficiency.

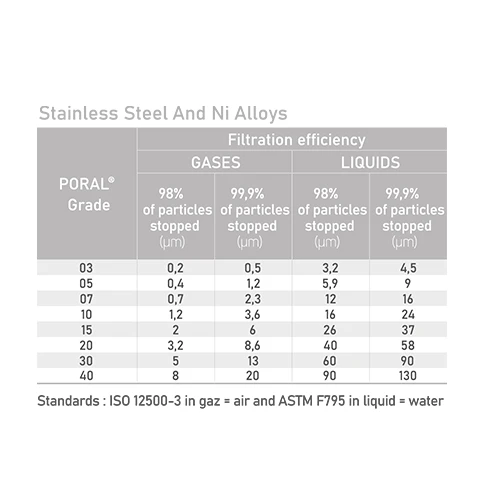

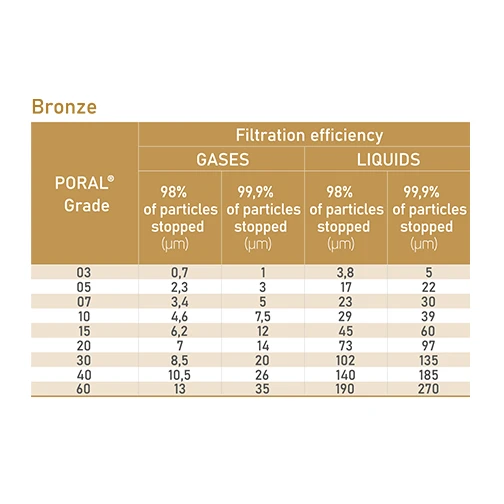

The efficiency values below are given for air and water at a given flow rate.

Stainless steel

filtration efficiency.

Stainless steel is known for its excellent filtration efficiency, particularly due to its controlled porous structure when sintered. Resistant to corrosion, high temperatures, and chemicals, it is ideal for filtering liquids or gases in demanding environments. Its smooth surface reduces particle buildup and makes cleaning easier, allowing for frequent reuse without performance loss. Thus, stainless steel offers a durable, reliable, and high-performance filtration solution in various industries, including food processing, pharmaceuticals, and petrochemicals

Bronze

filtration efficiency.

Bronze, often used in sintered form, provides good filtration efficiency thanks to its uniform porous structure. It is particularly suited for filtering liquids and gases in industrial applications, due to its resistance to wear and corrosion. Less expensive than some noble metals, it offers a solid balance between performance and durability. Filter-grade bronze is also valued for its ability to withstand repeated cleaning while maintaining its filtering properties.

PORAL activity

Our products

and their applications.

Our sintered porous filters are used extensively for filtration, but also for a wide range of industrial applications. Discover our complete range of components and their industrial applications.

Products

Porous sintered

Filters.

Discover a complete range of porous sintered filters designed to meet the needs of various industrial processes. Our product line includes discs, tubes, cartridges, cones, plates, and custom-shaped components, available in stainless steel, bronze, or specialty alloys. Each filter is engineered with controlled porosity and mechanical strength to ensure optimal performance in both standard and demanding environments.

Applications

Solutions for several

Industries.

PORAL’s porous filters are used across a wide range of industrial sectors, filtration, flow regulation, aeration, noise reduction, and pressure control, our components are engineered to perform reliably in demanding environments such as pharmaceuticals, water treatment, food processing, and chemical industries.

Do you have a question or a project?

Access our contact form and our teams will get back to you as soon as possible.